INTEGRATION SYSTEMS PROTOCOL

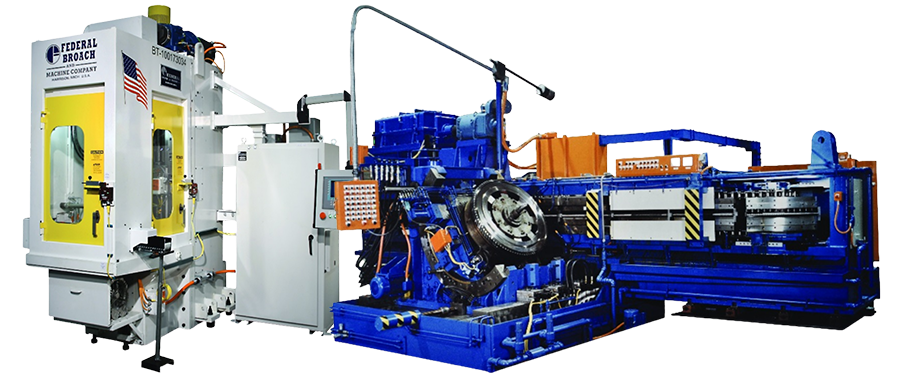

Custom Broach Machine Systems Integration and Turnkey Solutions

Custom Broach Machine Systems Integration and Turnkey Solutions

Federal Broach and Machine Company has been supplying broach machines since the mid 1970s. Starting in the early 2000s, we expanded our role to become a turnkey vendor for broach Integration systems.

Turnkey Systems Integration for Custom Broaching Applications

Federal Broach offers the capability to fully integrate our custom broaching machines within your production line. Our turnkey solutions include placing the machine into a work cell and developing the best part handling system for each unique broaching application.

At Federal Broach, we provide turnkey solutions that are totally assembled and debugged before leaving our factory to our customer’s destination.

The part flow from operation to operation can be done in many different ways, which include:

- Gravity Blue steel with drip pans for coolant collection.

- Power conveyor with drip pans for coolant collection.

- Fanuc or ABB robots and their end-of-arm tooling, designed to single or multiple parts.

- Automatic elevator for changing part heights entering and exiting machining operations.

- Total integration with controls hardware.

Full Integration with Your Production Line

Customers can supply Federal Broach with assets that pertain to the work cell, and we can assure that the asset gets integrated properly and eliminates all start-up challenges.

Superior Manufacturing Quality and Consistency

First-time quality is of the highest priority. With an SPC location for gaging at a customer’s frequency – along with ensuring the part is properly orientated before it enters the upcoming operation – precision quality is maintained.

Other Advantages of Our Turnkey Integration Solutions:

- Complete handshaking through Profibus-Profinet. Profibus-Profi-Net assures that the whole work cell is communicating properly

- Complete dry floor guarding and integral fencing engineered to meet all customer specifications

- Part cleanliness is crucial: we offer a part spinner and/or integrated blow off stations to help reduce waste and coolant carry-off

- We offer part turn over and part orientation stations to provide the best part possible

- Complete engineering and manufacturing of material handling to support various part types

Turnkey Internal Broaching Machines and Precision Tooling Solutions

Federal Broach is committed to our customers’ needs and excel at integrating them into the best work cells for their production requirements. We specialize in the total engineering, manufacturing, and integration of turnkey broaching solutions.

Through our engineering innovation and precision tooling capabilities, our company has remained a leader in the commercial broaching industry since 1952. Based in Central Michigan, our company operates an 96,000 square-foot facility capable of accommodating virtually any of the modern industry’s precision broaching applications.

Contact Us Today

Contact us today to learn more about our effective and dependable solutions for your projects.

We look forward to working with you and delivering exceptional results.