HOBBING TOOLS

Gear Hobs and Precision Hobbing Tools

Gear Hobs and Precision Hobbing Tools

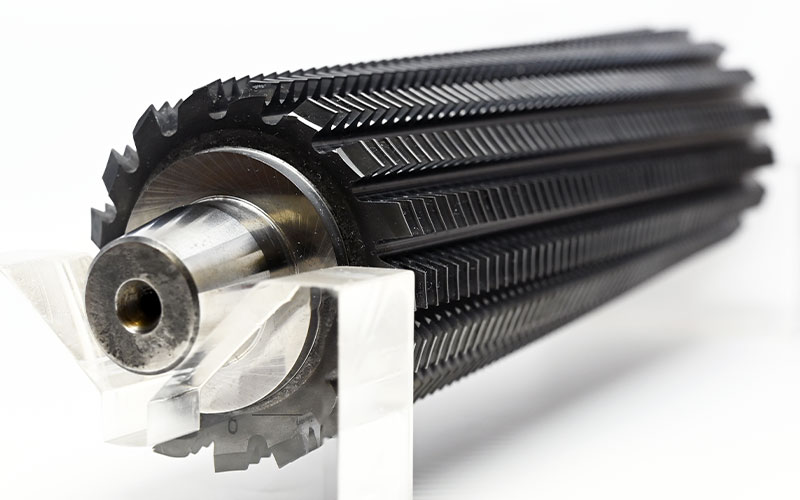

Federal Broach and Machine’s precision gear hobbing tools are engineered for superior performance. We produce a wide range of gear hobs built to perform reliably at the high cutting speeds required in today’s production gear cutting operations. Likewise, our custom gear hobs are surface treated to deliver very stable processing and an extremely long tool life for maximum productivity.

In addition to manufacturing a full line of gear hobs in standard and custom configurations, Federal Broach provides complete tool resharpening and recoating services. We are the one-stop shop for your precision gear hobbing needs.

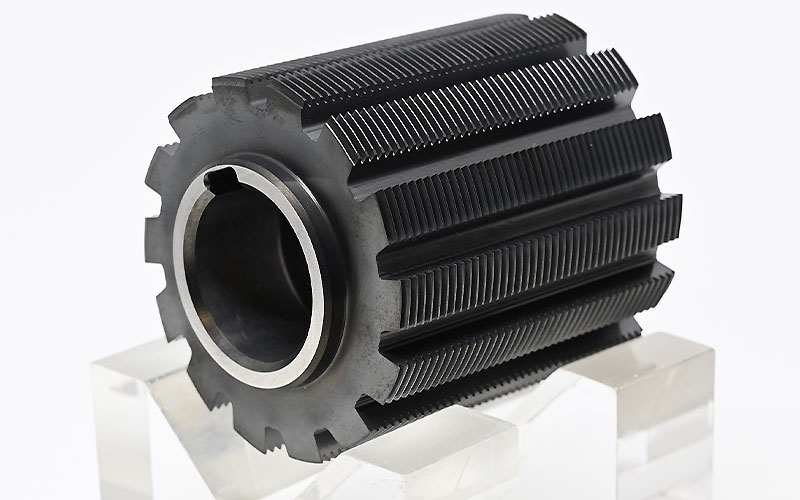

Gear Hob Specifications:

- Module: 0.3 to 10

- Maximum OD: 130mm

- Shank Type: 130mm

- Maximum Length: 240mm

- Shank Type: 410mm

- Bore Size: 10mm to 60mm

- Gash Lead Angle: ±15°

Engineered to Accommodate Virtually All Gear Hobbing Applications

Federal Broach offers a complete range of gear hobs such as non-topping, semi-topping, topping, finishing, roughing, pre-shaving or pre-grinding. Our tooling designs include hobs with or without protuberance, tip relief, full fillet radius, and various other custom configurations. Multi-start hobs, multi-gash hobs, and dry-cut hobs are also available.

Involute Gear Hobs

- Single-Thread Involute Hobs – The cutter features straight-angled sides that provide maximum accuracy and repeatability for production gear cutting projects that do not require additional tooth finishing processes.

- Multiple-Thread Involute Hobs – Multi-threaded hobbing tools feature numerous helical paths that multiply the number of tooth-cutting operations per rotation of the tool. For example, a double-thread hob rotates once for every two teeth cut into the part, while a triple-thread hob rotates once per three teeth. The multi-threaded cutting operations substantially increase production speed.

- Involute Spline Hobs – Involute spline cutters feature short straight teeth that are spaced evenly about the hob. This design centers stress distribution across the teeth for maximum strength and tool life.

Non-Involute Gear Hobs

- Straight-Key Spline Hobs – A special type of spline hob, straight-key hobs feature curved tooth forms designed for the production of precise single-depth cuts.

- Sprocket Hobs – Optimized for the production of extremely accurate finishes with various tooth forms, chain sprocket hobs can be designed in both single- and multiple-thread configurations.

Precision-Engineered Hobbing Tools and Gear Hobs

Federal Broach manufactures custom gear hobbing tools engineered for reliable performance in a wide range of production gear cutting applications. Our full selection of hobbing tools and gear hob cutters are designed around the specific needs of your products and precision gear-forming requirements.

Based in Central Michigan, our 96,000 square-foot facility utilizes some of the industry’s most capable CNC technology and CAD systems to develop a truly optimized tooling solution for your application. Our company is an ISO 9001:2015-certified American manufacturer dedicated to delivering superior tooling for your production line.

Contact Us Today

Contact us today to learn more about our effective and dependable solutions for your projects.

We look forward to working with you and delivering exceptional results.